The main function of the glass fiber drawing machine is to draw the glass solution into fibers and wind them into fiber rolls according to certain rules. This kind of equipment is widely used in the production process of glass fiber. Through a specific process, the glass material is converted into glass fiber with excellent properties such as high strength and high heat resistance.

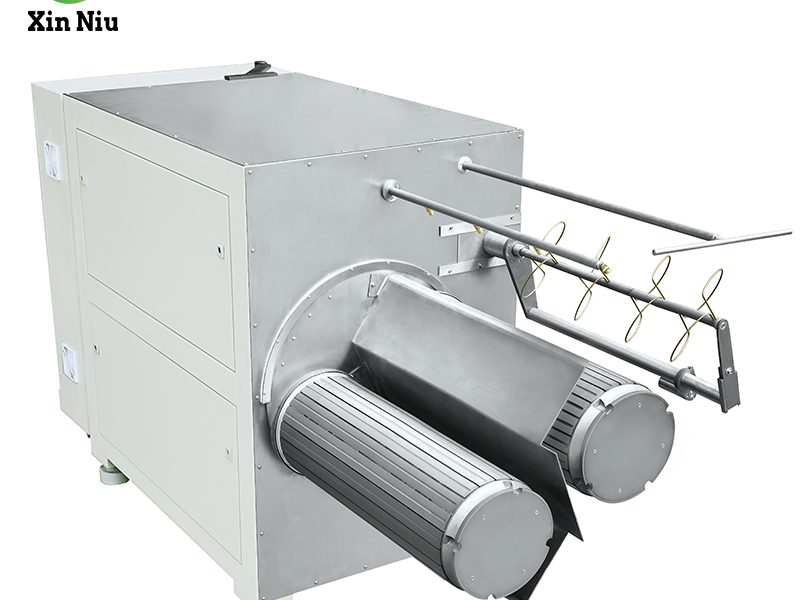

The main components of the glass fiber drawing machine include the fuselage, screw drive motor, drawing head, temperature control system, etc. The lower part of the fuselage is equipped with a screw drive motor, which is connected to the screw through belt transmission. The screw is equipped with a nut to form a screw nut movement pair. The drawing head consists of a motor, a coupling, a reel shaft and a reel installed on the shaft. There is a fiberglass cable arranger above the reel. The temperature control system fixed on the machine body is responsible for regulating the temperature of the entire process. Ensure that the glass solution can be smoothly drawn into fibers.

The process principle of the glass fiber drawing machine involves multiple steps. First, the glass raw material is melted, and then the molten glass is quickly drawn into filaments through the special design of the drawing head, and finally wound into fiber rolls according to certain rules. This process requires precise control, including temperature, drawing speed, etc., to ensure that the produced glass fiber has excellent properties.

Recent Comments