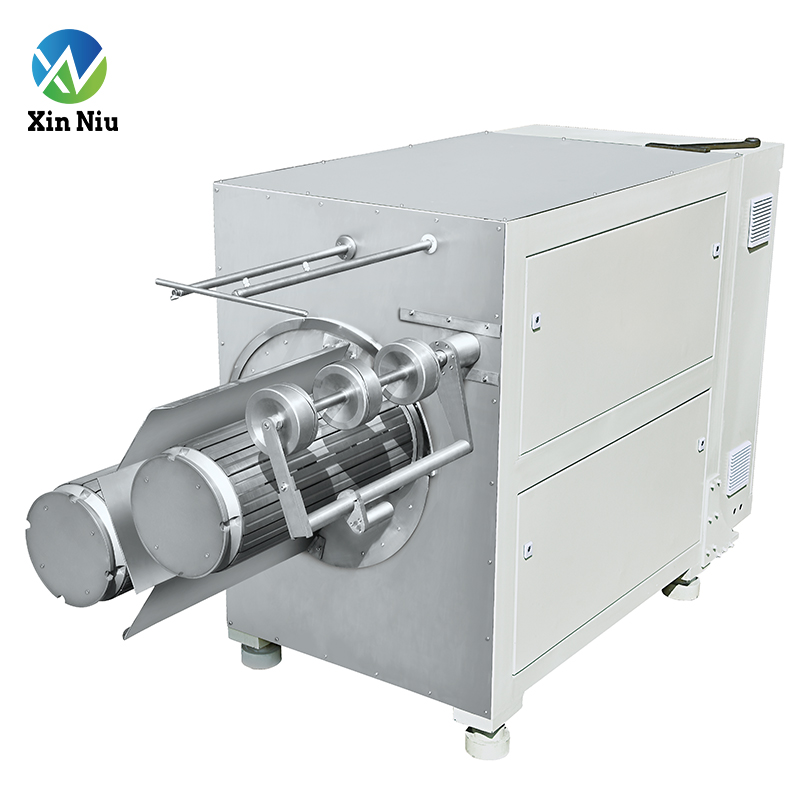

1、The whole adopts frame structure, neat and beautiful appearance, solid structure, reasonable layout, greatly reducing the vibration of the body.

2、The turning system adopts cast iron turntable, which is flexible in rotation, and at the same time, it is driven by self-service motor, which is accurate and reliable in positioning.

3、Spindle adopts high-precision precision bearings directly connected with the motor. It can also adopt belt precision transmission, the two kinds of transmission is stable and reliable, the control is more accurate, and the maintenance is simple and convenient.

4、Conservative cage line support mechanism, the drive shaft end by the sealing device, effectively preventing the shaft end of the water, to extend the service life.

5, the head is composed of spring type and air up structure, the head is made of high-strength aluminum alloy, which is wear-resistant, corrosion-resistant and durable.

6、Control cabinet installation wiring standardized flow operation cabinet electrical parts. Platting standardized and orderly, clear lines.

7, backpack type control cabinet structure, with cable saving, reduce signal interference. Installation and transportation is convenient.

8, electronic control system using PLC programmable DCS system, self-service motor control, high control accuracy, reliable operation, equipped with a color man-machine interface all functions. Parameters can be set on the touch screen.